Williams, Second (CRC Press and Woodhead Publishing, Boca Ratón, 2009), pp. Draget, in Handbook of Hydrocolloids, ed.

Williams, Handbook of hydrocolloids, 2nd edn. Taylor & Francis Group, Boca Ratón, 2006), pp. Smidsrod, in Food polysaccharides and their applications, ed.

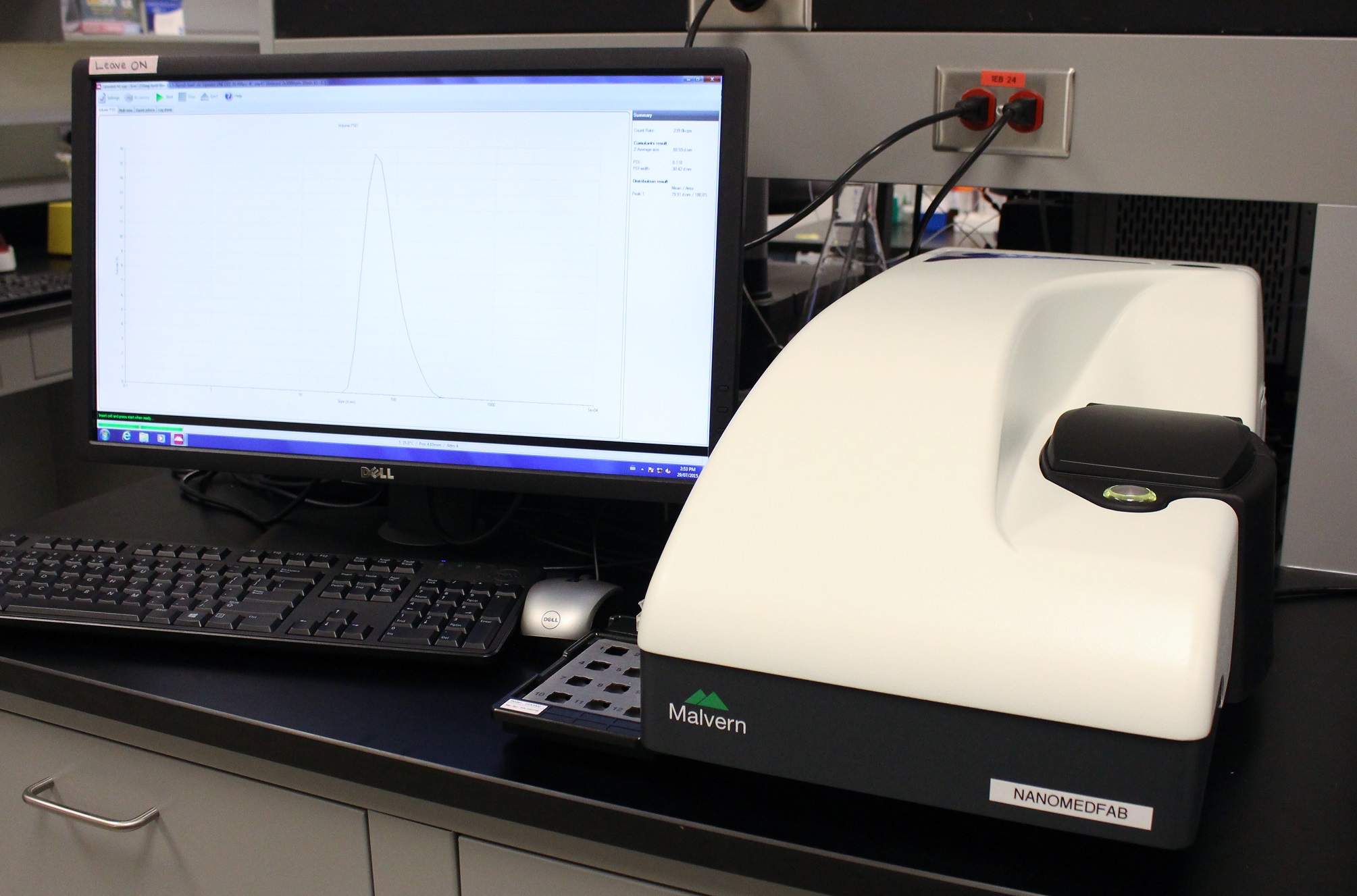

The results obtained in this work lay the basis for the rational design of polysaccharide-based nanolaminates in the food sector. Microscopic examinations revealed the presence densely packed structures that corresponded to alginate/chitosan nanolaminates, having an estimated thickness of 700 nm. Chitosan layers showed higher contact angle values (80°), indicating a more hydrophobic behavior. Contact angles obtained in alginate layers were ≈ 10°, being mostly hydrophilic. Alginate layers were negatively charged, whereas chitosan layers were positively charged. The surface ζ-potential of nanolaminates changed depending on the last polysaccharide deposited. The absorbance increased as a function of the number of polysaccharide layers on the substrate, suggesting an increase in the mass adsorbed. Alginate/chitosan nanolaminates were characterized in terms of UV-visible spectroscopy, surface ζ-potential, contact angle, DSC analysis and SEM. The ζ-potential, viscosity and whiteness index of the solutions were assessed before the assembly. The effect of pH, ionic strength and polysaccharide concentration on the properties of the adsorbing solutions was also evaluated. The objective of this study was to form and characterize the physicochemical properties of nanolaminates assembled from alginate and chitosan solutions. However, the final properties of nanolaminates may be affected by the conditions of the adsorbing solutions. Biopolymer-based nanolaminates obtained by the layer-by-layer technique can also be used to change the surface properties of food products or food contact materials. The alternate deposition of oppositely charged materials (layer-by-layer technique) is an effective approach to functionalize materials.

0 kommentar(er)

0 kommentar(er)